FSW Plants - ECOLOGICAL & ECONOMIC

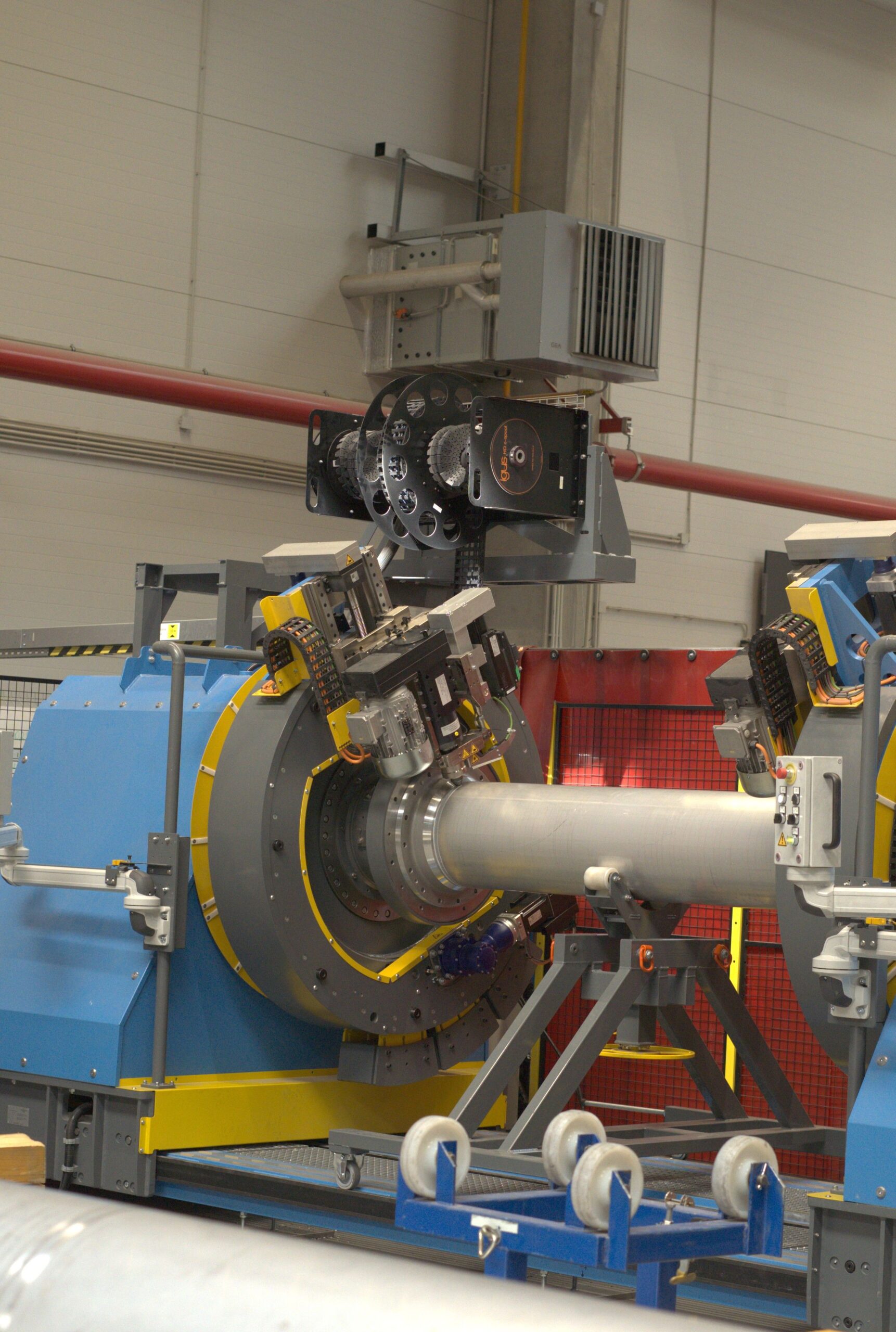

FSW plant Orbital (Arturito)

The orbital friction stir welding machine is used for welding (for welding or joining) of rotationally symmetrical parts. The fully automated welding process of the machine is easy to operate by one operator. After equipping and setting up the machine with themn parts to be welded, the process starts without the need for that further intervention is necessary. The friction stir welding process takes place in three steps:

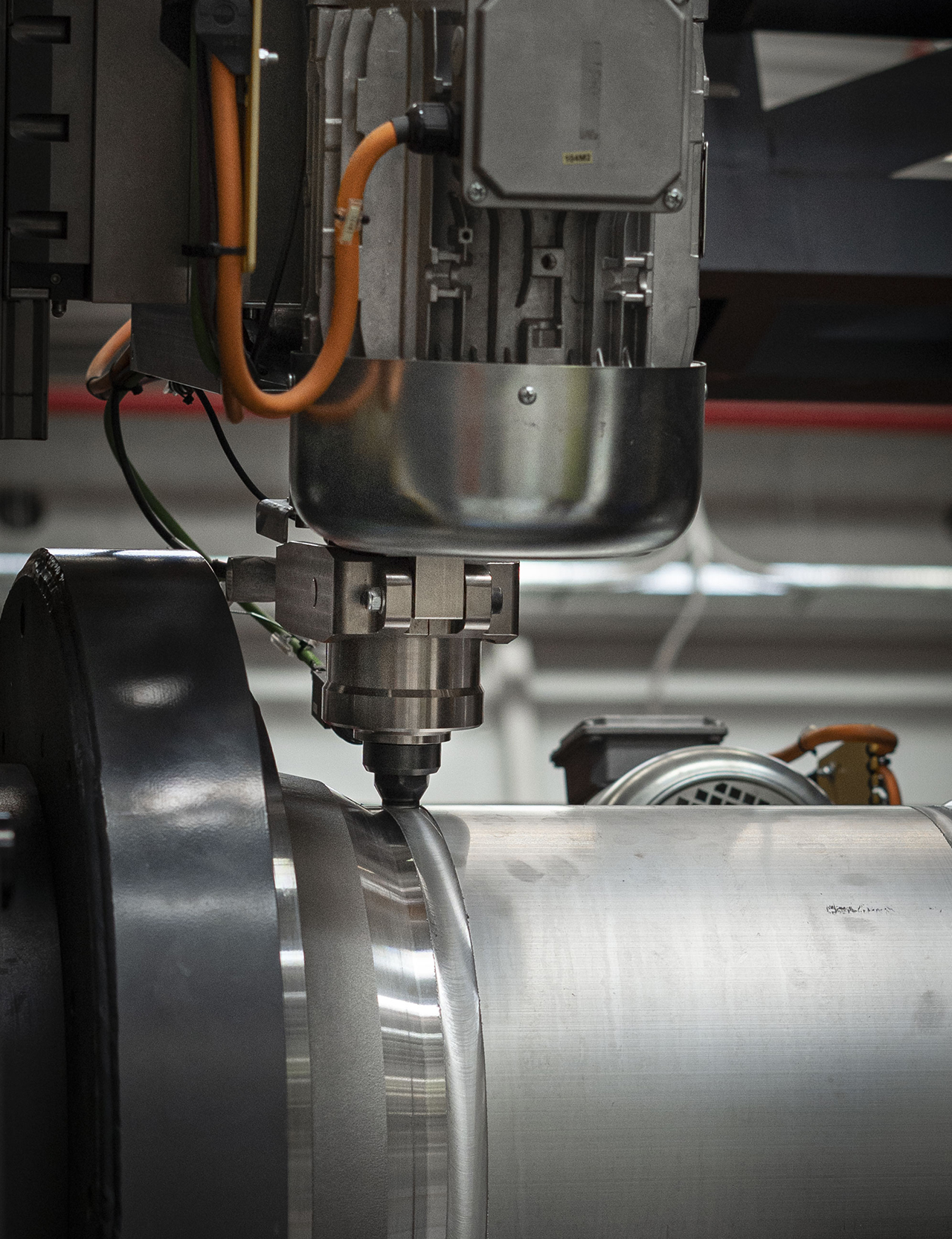

The FSW tool, consisting of a pin and a shoulder, penetrates the joint gap of the parts to be welded with the rotating pin. As soon as the pin has reached the necessary depth, pressure is applied to the surface of the parts to be welded by means of the shoulder. The friction between the shoulder and the component surface builds up the necessary process temperature.

After a short dwell time, the feed motion starts and the welding tool moves orbital around the parts to be welded until a complete pass is welded.

3. in order not to leave any undesirable end crater caused by the pin penetrating into the parts to be welded, the pin is retracted at the end of the welding.

After finishing the welding, the equipment goes to the home position. The parts have a low temperature so that the operator can start removing the part immediately after welding.

During the welding process, the operator has the possibility to follow the welding on a monitor. The control system also makes it possible to record and evaluate the parameters of the welding process. After the welding process, signals or information on the status or also on the part-Iidentification can be output. Adaptations according to customer-specific requirements for integration into a modern production line are also possible. also possible.